WATER TREATMENT PLANTS

Water Treatment System for Bottled Water or Packaged Drinking Water is Optimum Design System which consist of Various Processes or Equipments to treat Water to the level of best purification where once bottled, it should stay for long. Following Processes are necessary to treat water to desired level.

The First Process is to Pump the raw water from the source which can be Open well,  Bore / Tube Well, River Water etc. (Normally River water is the alternative only in case the other two options are not available) to the RAW WATER STORAGE TANK. The pump required would depend upon the uplift of the water & distance required to be covered from the source to the tank.

Bore / Tube Well, River Water etc. (Normally River water is the alternative only in case the other two options are not available) to the RAW WATER STORAGE TANK. The pump required would depend upon the uplift of the water & distance required to be covered from the source to the tank.

Raw water tank can be either HDPE Tanks (Example: Sintex tanks) / ZnAl Tanks or Concrete tanks,  the Concrete Tanks can be located either in the ground or above the ground level. Having the tanks under the ground level is always feasible. Concrete tanks should be tiled with White tiles and manhole facility to be provided to enable regular cleaning of the tanks.

the Concrete Tanks can be located either in the ground or above the ground level. Having the tanks under the ground level is always feasible. Concrete tanks should be tiled with White tiles and manhole facility to be provided to enable regular cleaning of the tanks.

Storage capacity should be maintained at least twice of the product output per day  Example : If Product Output is 2000Lph , the storage capacity installed should be min. 20000 Litres and the storage should be made in individual tanks having double the capacity of the output i.e. 4 nos. of HDPE tank are to be installed of 5000 Litre capacity each.

Example : If Product Output is 2000Lph , the storage capacity installed should be min. 20000 Litres and the storage should be made in individual tanks having double the capacity of the output i.e. 4 nos. of HDPE tank are to be installed of 5000 Litre capacity each.

It is used to cause the suspended solids that may be present in water to coagulate and settle out. By coagulation we mean that the very fine particles of suspended matter come together to become a larger cluster which will settle more easily than the smaller suspended particles. Alum and Lime are normal Coagulants used, this is a optional process and is done in the raw water tank and is done only in case the raw water has more suspended solids which may harm the further filtration process.

PROCESS: 2) CHLORINE DOSING OR OZONE DISINFECTIONRaw water may contain living microorganisms and organics, which are objectionable to the Membrane as it, may cause fouling and further oxidation to deteriorate the performance of the filters and the RO membrane. This Raw water may contain oxidized or unoxidised ferrous which can be converted to ferric oxide with the addition of chlorine, which will further settle down in storage tank. The chemical used for this is Sodium Hypo chloride, which is locally available in market in liquid concentrate or anhydrous form. About 3-5 PPM of sodium hypochlorite solution is dosed in raw water storage tank as standard measure. This reacts with water to form a hypo chlorite acid which acts as disinfecting agent. (Actual quantity of dosage may be obtained from the Plant designers)

This process can be made manually or can be automated depending upon requirement. For automation one no. HDPE hypochlorite solution preparation tank along with one nos. of electronic diaphragm dosing pump is provided. Dosage rate is adjusted as per the actual requirement, which may very on case to case basis.

Ozone is a highly effective oxidizing agent and is a strong disinfectant and can be used in place of chlorine as it does not leave any kind of colour and odour residue in water after treatment and proves to be more efficient than Chlorine. A equivalent Ozone generator is required for this purpose and is dosed online in the piping’s and a UV treatment is given just before the RO to neutralize the effect of Ozone since presence of ozone in water can cause fouling of RO Membranes. This may increase the capital investment initially but has no recurring expense in comparison to the chemical cost required for chlorine and thus is highly recommended for initial disinfection.

PROCESS: 3) PRESSURE SAND FILTER: (TSS)The chlorinated water is first pumped to this section which is called the Pressure Sand Filter unit  which is in series prior feeding to the R.O.Plant. A Pump is used for the purpose to generate the required flow rate and pressure. Pressure Sand Filter Unit is provided for removal of suspended matters & turbidity from raw water. TSS Unit is a vertical Pressure Vessel. Internally, it is fitted with bottom collecting system. A uniform grades silica quartz sand is charged on the supporting media of pebbles and gravel’s. This unit is fitted with frontal pipe work and Multiport Valve externally.

which is in series prior feeding to the R.O.Plant. A Pump is used for the purpose to generate the required flow rate and pressure. Pressure Sand Filter Unit is provided for removal of suspended matters & turbidity from raw water. TSS Unit is a vertical Pressure Vessel. Internally, it is fitted with bottom collecting system. A uniform grades silica quartz sand is charged on the supporting media of pebbles and gravel’s. This unit is fitted with frontal pipe work and Multiport Valve externally.

During service cycle water is passed in down ward direction through sand bed, thus entrapping  suspended matter & turbid particles. Over a period of time, sand bed gets choked due to suspended matters resulting higher pressure drop and lesser floe. At this stage filter bed need to be backwashes. This is indicated by the pressure drop across the sand bed if the same increases beyond the specified limit (0.5 kg/cm²) or quality of filtered water determinates which ever is earlier. Regeneration process is carried on which involves backwash & rinsing of Sand Bed.

suspended matter & turbid particles. Over a period of time, sand bed gets choked due to suspended matters resulting higher pressure drop and lesser floe. At this stage filter bed need to be backwashes. This is indicated by the pressure drop across the sand bed if the same increases beyond the specified limit (0.5 kg/cm²) or quality of filtered water determinates which ever is earlier. Regeneration process is carried on which involves backwash & rinsing of Sand Bed.

For backwashing: Service water is passed in reverse direction of service cycle to loosen the filtering  media bed. Due to this, entrapped suspended matters get free and come out along with effluent water. Backwashing is continued for about 10- 15 minutes or till the effluent coming out is clear.

media bed. Due to this, entrapped suspended matters get free and come out along with effluent water. Backwashing is continued for about 10- 15 minutes or till the effluent coming out is clear.

For Rinsing of Sand Bed: Service water is passed in down ward direction to settle down the sand bed. The effluent water is drained for about 5 minutes time to ensure all unclear water is drained down. This Process is completely done by just changing the valve position of the multi port valve provided

Lesser the velocity higher is the effective filteration, Sand filters used by reputed brands like Bailley, Aquafina, Kinley etc operate sand filters at lower velocity ensuring higher filteration efficiency.

Normally this process is to be carried out after every day operation to enhance the performance of the Filter. The Material of construction can be either Mild Steel, F.R.P. (Fiber Reinforced Plastic) or Stainless Steel, which can be chosen as per requirement.

PROCESS: 4) ACTIVATED CARBON FILTER: (ACF)Raw water contains Colour, Odour, Chlorine & Organics in different proportion, which is objectionable for potable application, and hence, it is a necessity to remove the same from water. If raw water is chlorinated for dis-infection, it is necessary to remove the free Chlorine present in the water before it is being fed to the R.O System. Chlorine being a strong oxidizing agent can damage the R.O. Membranes. Activated Carbon can remove the free Chlorine, Odour & Colour from the water after it is passed through the carbon bed. These Carbon granules have larger surface area and specific property to absorb organics.

The Filter is fitted with strainer on bottom collecting system. The unit is fitted with frontal pipe work & Multi Port Valve externally. A granular activated carbon is charged on the supporting media of Coarse & Fine Silex. During service cycle water is passed in down ward direction through Carbon Bed, which removes Chlorine & Odour from water.

When pressure drop across the Carbon Bed increased beyond the specified limit of (0.8 kg/cm²) or quality of filter water deteriorates, whichever is earlier the unit is isolated for regeneration. The regeneration involves backwashing & rinsing of Carbon Bed. The life of carbon gets exhausted over a period of time, which can be checked during laboratory testing. Particularly iodine value is most important for this application. Normally coconut shell activated carbon with steam activated acid wash carbon is used with an iodine value above 1000 ppm.

Lesser the velocity higher is the effective adsorbtion, carbon filters used by reputed brands like Bailley, Aquafina, Kinley etc operate carbon filters at lower velocity ensuring higher contact time of water with the media

Also Lead & Lag carbon filters are used in for better efficiency and to act as a standby during super chlorination, super chlorination is done to deactivate bacterial regeneration in the carbon column

Steam clarification is also used with air scouring for higher capacity filters

Normally this process is to be carried out after every day operation to enhance the performance of the Filter. The Material of construction can be either Mild Steel, F.R.P. (Fiber Reinforced Plastic) or Stainless Steel, which can be chosen as per requirement.

PROCESS: OPTIONAL): SMBS DOSINGSodium metabisulfite is an inorganic compound of chemical formula Na2S2O5. The substance is sometimes referred to as disodium (metabisulfite, etc.). This is used to remove any residual Chlorine from water and makes 100% sure that chlorine does not pass through the RO membranes. Although ACF takes care of the same, this is an optional process and depends upon requirement. This chemical will also add up in the water processing cost. This process is automated. For automation one no. HDPE solution preparation tank along with one nos. of electronic diaphragm dosing pump is provided. Dosage rate is adjusted as per the actual requirement, which may very on case to case basis.

PROCESS: OPTIONAL): SOFTNERWater Softeners uses the proven Technique of Counter Current Regeneration, this involves the flow of brine used for regeneration & the flow of raw water during Service, in opposite directions to each other. This ensures the residual hardness in treated water is always less than 5 ppm as CaCO3 throughout the cycle. Ion Exchange resin in Sodium form is used to Exchange Sodium ions for hardness forming calcium and magnesium, thus producing soft water. At the end the service cycle, the ion exchange resin is regenerated with Salt solution, to keep unit ready for next service cycle. The ACF Unit can be M.S / FRP vertical pressure vessel. The unit is fitted with frontal pipe work & Multi Port Valve externally.

PROCESS: 5) ANTI SCALENT DOSING SYSTEM: (ASD)The hardness of water mainly depends upon the following two constitutions of the salts of calcium & magnesium which are likely to be precipitated if concentration exceeds its solubility limit & it may result in flaw to the R.O. membranes resulting into scaling which ultimately leads to poor treated water quality from R.O. System. To prevent this scaling effect a anti Scalene dosing (scale inhibitor) dosing system is provided. Normally a scale inhabitator like Hypersperse MDC150, Perma care 191 / Flocon 260 or equivalent chemical is dosed in feed water. Dosage rate is 4-5 ml/liter in diluted form, which may further depend upon the quality of the raw water. A HDPE / SS chemical preparation tank with an electronics diaphragm type dosing pump is provided for this process. This system is mainly installed for the safety of the RO membranes and enhances its performance.

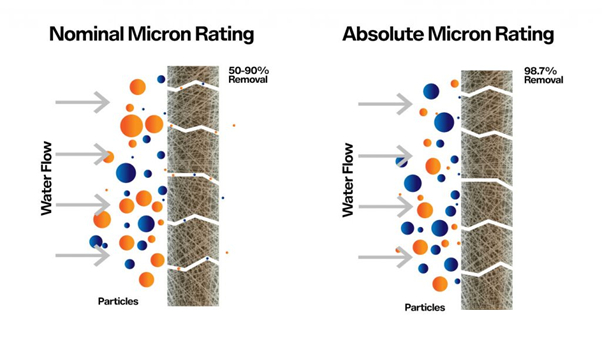

PROCESS: 6) PRE MICRON FILTERS: (MF)Pre Micron Filters are Micron Cartridge Filter having Series of filtration with the combination of any  two of the 20-Micron, 10 Micron, 5 Micron Filters. Depending upon quality of water. Nominal & Absolute Micron Cartridge. This is a Consumable Cartridge and should replace it after Days of operation normally around one to two months. This for Extra Safety of the Product water as it comes through the followed filtration and there are some chances to slippages for any particles which can be stopped through the Cartridge this micron cartridge filter will also take care of microbiological growth up to 5 micron. These filters are usually housed in PP / PVC or SS housing

two of the 20-Micron, 10 Micron, 5 Micron Filters. Depending upon quality of water. Nominal & Absolute Micron Cartridge. This is a Consumable Cartridge and should replace it after Days of operation normally around one to two months. This for Extra Safety of the Product water as it comes through the followed filtration and there are some chances to slippages for any particles which can be stopped through the Cartridge this micron cartridge filter will also take care of microbiological growth up to 5 micron. These filters are usually housed in PP / PVC or SS housing

PROCESS: 7) REVERSE OSMOSIS SYSTEM & High Pressure Pumping

The Principle of Osmosis & Reverse Osmosis:

PROCESS: 7) REVERSE OSMOSIS SYSTEM & High Pressure Pumping

The Principle of Osmosis & Reverse Osmosis:

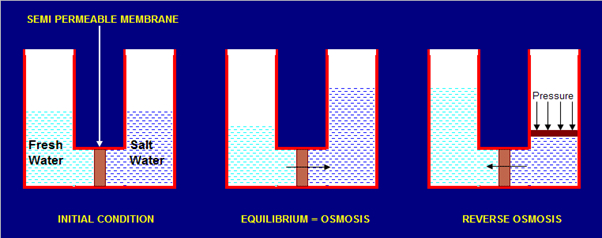

Osmosis is the net movement of water across a selectively permeable membrane driven by a difference in solute concentrations on the two sides of the membrane. A selectively permeable membrane is one that allows unrestricted passage of water, but not solute molecules or ions.

The following Diagram illustrates the Principle of Osmosis:

The Reverse Osmosis:

The Reverse Osmosis:

Reverse osmosis occurs when the water is moved across the membrane against the concentration gradient, from lower concentration to higher concentration. To illustrate, imagine a semi permeable membrane with fresh water on one side and a concentrated aqueous solution on the other side. If normal osmosis takes place, the fresh water will cross the membrane to dilute the concentrated solution. In reverse osmosis, pressure is exerted on the side with the concentrated solution to force the water molecules across the membrane to the fresh water side.

For Reverse Osmosis Process to take place feed pressure of the water is raised. For this purpose a Vertical Multistage Centrifugal High Pressure Pump in SS construction is provided along with the R.O. System which requires operating pressure of about 16-18 kg/cm². High-pressure pump is fitted with SS discharge pipe work with necessary control valves. Necessary instruments like a High Pressure Switch, Pressure Gauge and re-circulation valves are provided for safer operation of system.

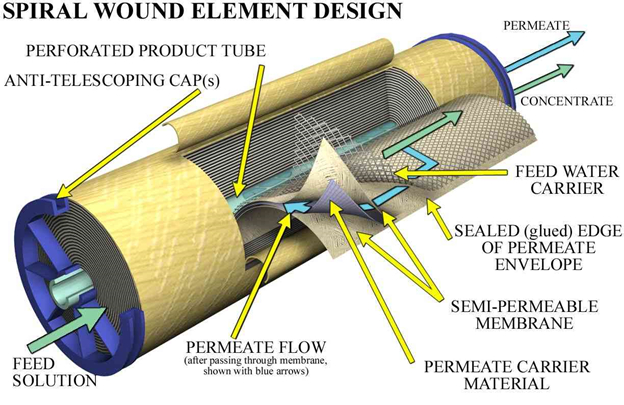

REVERSE OSMOSIS SYSTEM: (ROM)In the Reverse Osmosis System the membrane will reject around 98 – 99% of total  dissolved solids by the principle of `Osmosis’. This system consists of a R.O. Module assembly mounted on MS / SS Skid. High pressure rating FRP / SS Pressure Vessel is fitted on the skid which houses spirally wound membrane elements in series. The membrane is made up of TFC (Thin Film Composite). The number of membranes will depend upon the capacity of the output required. Normally used membranes are 4” x 40” (4040) membranes with derived output of approx. 250Litres / Hour and 8” x 40” (8040) membranes with derived output of approx. 1000 Litres / Hour.

dissolved solids by the principle of `Osmosis’. This system consists of a R.O. Module assembly mounted on MS / SS Skid. High pressure rating FRP / SS Pressure Vessel is fitted on the skid which houses spirally wound membrane elements in series. The membrane is made up of TFC (Thin Film Composite). The number of membranes will depend upon the capacity of the output required. Normally used membranes are 4” x 40” (4040) membranes with derived output of approx. 250Litres / Hour and 8” x 40” (8040) membranes with derived output of approx. 1000 Litres / Hour.

In RO System, Feed / Softened water is divided into two streams viz. Product & Reject water. Product water is treated water having lesser TDS. Reject water is highly concentrated water, which is not to be used for any purpose but drained. Feed water at elevated pressure is first fed to first Pressure Vessel; treated water is collected in center core tube. Treated water from each membrane is collected jointly in a common product water storage tank and reject is drained.

This reject water can be further used for flushing washing and gardening activities in the plant. The reject water can also be dumped into a sump in the ground where the water can percolate in the ground and recharge the ground water table.

The figure illustrates a typical RO Membrane:

Some of the Available membranes arranged in performance order are: TORAY, HYDRANAUTICS, DOW, FILMTECH etc.

PROCESS: 8) PRODUCT WATER COLLECTION TANK: (PWCT)

Here the R O treated water (the product) is collected in a Collection tank which is generally 50 to 100 % of the RO output capacity. Water from the RO generally does not have enough pressure to pass through further Filtration elements and hence is thereby required to be re pressurized so that it can pass forward through the further process.

| COMPARISION | ||

| TYPE | Corrugated | Plain |

| Shell Thickness | 0.8 to 1 mm | 2.5 to 3 mm |

| Build quality | Poor | Very good |

| Cost | Low | Very high |

| Life | Low | Very high |

| Sanitisation | Low | Very high |

This is also an optional process and is required only if the RO treated water is not maintaining its pH value in the desired limits. This process is automated. For automation two no. HDPE solution preparation tank along with respective two nos. of electronic diaphragm dosing pump is provided. One tank contains Acid chemical in dilute form and one tank contains Alkali chemical in dilute form, Dosage rate is adjusted as per the actual requirement, which may very on case to case basis. The kind of chemical to be used is referred by the plant designer. For Mineral dosing also similar kind of technique is used and normally Magnesium Sulphate and Potassium Bicarbonate is used, Dosage rate is adjusted as per the actual requirement, which may very on case to case basis

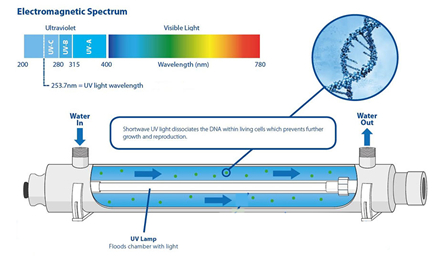

PROCESS: 9) ULTRA VIOLET STERILIZER: (UVS)Though R.O. treated water is free from all the microbiological impurities like Bacteria,  Virus, etc. it may redevelop again in water during prolonged storage. For disinfection of water it is essential for the water to be treated with U V before Storage, Filling & Sealing in bottle. Hence, a online Ultra Violet Sterilizer is provided for disinfection of R.O. treated water before filling in pre-cleaned PET Bottles. The water to be disinfected is passed through U.V. System, which consists of U.V. Tubes, which radiates high intensity Ultra Violet Rays, which in turn kills, the micro organisms. This system consists of an SS finished surface housing with Ultraviolet Lamps fitted in it. The water to be treated is surroundings this tubes during treatment. An electrical system is provided for production of high voltage required for UV Ray’s generation.

Virus, etc. it may redevelop again in water during prolonged storage. For disinfection of water it is essential for the water to be treated with U V before Storage, Filling & Sealing in bottle. Hence, a online Ultra Violet Sterilizer is provided for disinfection of R.O. treated water before filling in pre-cleaned PET Bottles. The water to be disinfected is passed through U.V. System, which consists of U.V. Tubes, which radiates high intensity Ultra Violet Rays, which in turn kills, the micro organisms. This system consists of an SS finished surface housing with Ultraviolet Lamps fitted in it. The water to be treated is surroundings this tubes during treatment. An electrical system is provided for production of high voltage required for UV Ray’s generation.

During storage & due to atmospheric or any other factor contamination may take place in R O treated  water and also after UV sterilization dead bacteria’s are present in water. Hence, the water is once again passed through a set of micron cartridge filter. This are S.S.316 Vessel fitted internally with P.P spun micron cartridge elements having absolute ratings of either 0.45 micron or 0.2 microns or combination of both depending upon requirement, each which removes all bacterial impurities present in the water and make the water free of particulates.

water and also after UV sterilization dead bacteria’s are present in water. Hence, the water is once again passed through a set of micron cartridge filter. This are S.S.316 Vessel fitted internally with P.P spun micron cartridge elements having absolute ratings of either 0.45 micron or 0.2 microns or combination of both depending upon requirement, each which removes all bacterial impurities present in the water and make the water free of particulates.

Though R.O. System along with micron filters and UV sterilizer reject all the micro – organisms like bacterial & virus there always remains a chance that they may redevelop in packed bottles over a period of time. Ozone being a strong oxidizer and disinfectant acts to disinfect the Product water prior to filling. This is very much essential to ensure good Packaged Drinking Water Quality as per the standards. This Ozone Generator will actually help in providing enhanced Shelf Life to the water in packed condition over a period of time. Also this process can add some taste and rectify the pH in the product water. The ozone generator provided herein uses atmospheric oxygen to generate Ozone using corona discharge technology. Oxygen concentrators are used in combination with the generators for higher concentration ratio.

Ozone is injected directly using a venturi in the permeate feed lines to ensure max. concentration for smaller capacity lines

For Higher capacity lines Ozone recirculation tank in SS 316 grades are used along with ozone recirculation pump to increase concentration in permeate

This completes the Treatment and Processing of the Raw Water to Product Water as per BIS Standards for Packaged Drinking Water. The Product water after this will be used to be packed in different forms of Packing.