SUGAR SYRUP MANUFACTURING PROCESS

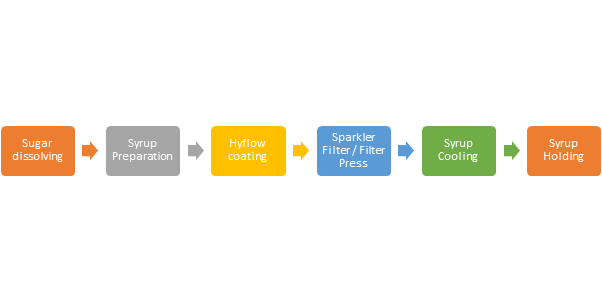

Syrup Preparation Flow

SYRUP DISSOLVING

Granular Sugar has to be dissolved in required proportion of water in a Jacketed Steel tank

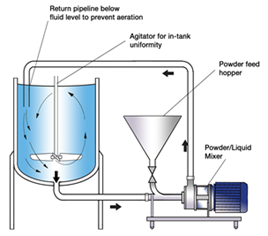

The system can be automated as shown in the figure beside using a sugar venturi table or powder feed hopper for sugar loading and shear pump which shall mix the sugar and water and deliver it to the jacketed tank. this process is highly advisable as it has following benefits:

- The combination of granule size reduction and vigorous mixing dramatically reduces mixing times.

- 66% sugar syrup can be produced at ambient temperature.

- Increased versatility allows the manufacturer to use sugar in granulated or syrup form.

This automation is widely used in large scale applications whereas, in lower capacities sugar is directly dumped in the tank manually and proportionate water is added.

SYRUP PREPARATION

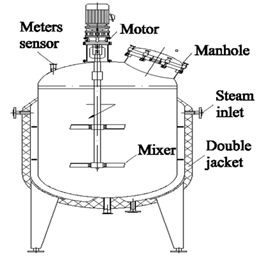

Stainless Steel Jacketed tanks are used for dissolving, as heat decreases the time of dissolution and further helps in preparation of syrup with controlled heating.

The jacketing helps in reducing loss of heat and increases the specific calorific value thereby reduced power / fuel consumption

Electrical and Steam jacketed tanks are available, Large scale lines generally prefer steam jacketed heating as it is controlled and the heat can be uniformly distributed and the power consumption is low and thereby proves economical, Electrical jacketed are advisable only upto 500 LPH production capacities.

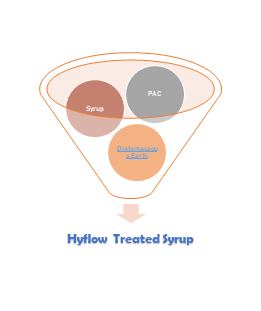

HYFLOW COATING

This is a process for removing colour, turbidity, flavour, and odour from impure sugar syrups.

Diatomaceous earth is a great filtration media and filter aid because diatoms have a wide variety of shapes and a honeycomb-like structure.

The pores within and between the cell walls are so small, that they trap bacteria, clay particles, some viruses, and other suspended solids from liquids, leaving liquids cleaner and with drastically reduced solids and contaminant levels. Purified sugar syrup is then filtered with or without activated carbon and small amounts of a filter aid to produce a sugar syrup with substantially reduced colour, turbidity, and odour.

SPARKLER FILTER

In Sparkler Filter Press Liquid syrup is pumped through the central channel of the cartridge  from the bottom of the body. Suspended particles are retained on the filter media resting on the filter plate. Clean filtrate emerges out from the peripheral holes of the plate, into the tank and comes out from the bottom outlet.

from the bottom of the body. Suspended particles are retained on the filter media resting on the filter plate. Clean filtrate emerges out from the peripheral holes of the plate, into the tank and comes out from the bottom outlet.

Filter tank wall does not come in contact with the un-filtered liquid, hence remains clean.

The Filter is now void of any impurities and is now suitable to be impregnated with the drink

SYRUP COOLING

A heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact.

Syrup before been used for mixing has to be cooled to a certain temperature based on the type of drink hence PHE are used to obtain desired cooling temperatures

The ready syrup is then held in a Stainless-Steel Storage tank with agitation to avoid settling and crystallisation of syrup.